1. Iimfuno zobugcisa zokutshaja iinqwaba

Ngokwendlela yokutshaja,iinqwaba zokutshaja ze-evzahlulwe zibe ziintlobo ezintathu: iipali zokutshaja ze-AC,Iinqwaba zokutshaja zeDC, kunye neepali zokutshaja ezidityanisiweyo ze-AC kunye ne-DC.Izikhululo zokutshaja zeDCngokubanzi zifakwa kwiindlela ezinkulu, kwizikhululo zokutshaja nakwezinye iindawo;Izikhululo zokutshaja ze-ACngokubanzi zifakelwa kwiindawo zokuhlala, kwiindawo zokupaka iimoto, kwiindawo zokupaka ezindleleni, kwiindawo zeenkonzo zendlela ezinkulu nakwezinye iindawo. Ngokweemfuno zomgangatho weState Grid Q/GDW 485-2010,inqwaba yokutshaja imoto yombaneumzimba kufuneka uhlangabezane nale miqathango ilandelayo yobugcisa.

Iimeko zokusingqongileyo:

(1) Ubushushu bendawo yokusebenza: -20°C~+50°C;

(2) Ukufuma okunxulumeneyo: 5% ~ 95%;

(3) Ukuphakama: ≤2000m;

(4) Umthamo we-Seismic: ukukhawulezisa okuthe tye komhlaba yi-0.3g, ukukhawulezisa okuthe nkqo komhlaba yi-0.15g, kwaye izixhobo kufuneka zikwazi ukumelana namaza amathathu e-sine asebenza ngaxeshanye, kwaye ukhuseleko kufuneka lube ngaphezulu kwe-1.67.

Iimfuno zokuxhathisa okusingqongileyo:

(1) Inqanaba lokhuseleko lweitshaja ye-eviqokobhe kufuneka lifikelele: ngaphakathi kwi-IP32; ngaphandle kwi-IP54, kwaye lixhotyiswe ngezixhobo zokukhusela imvula nelanga ezifunekayo.

(2) Iimfuno ezintathu ezichasene (nokufuma, ukubola, ukutshiza okuchasene netyuwa): ukhuseleko lwebhodi yesekethe eprintiweyo, izihlanganisi kunye nezinye iisekethe kwitshaja kufuneka ziphathwe ngokhuseleko oluchasene nokufuma, ukubola, kunye nokutshiza ityuwa, ukuze itshaja isebenze ngokuqhelekileyo kwindawo engaphandle efumileyo nequlethe ityuwa.

(3) Ukhuseleko lokulwa nomhlwa (ukulwa ne-oxidation): Iqokobhe lesinyithi leisikhululo sokutshaja se-evkwaye isibiyeli sesinyithi esiveziweyo kunye neenxalenye zaso kufuneka zithathe amanyathelo okulwa nomhlwa anomaleko ophindwe kabini, kwaye iqokobhe lesinyithi elingenayo i-ferrous kufuneka libe nefilimu yokukhusela i-oxidation okanye unyango lwe-anti-oxidation.

(4) Iqokobhe leinqwaba yokutshaja ye-evkufuneka ikwazi ukumelana novavanyo lwamandla okuchaphazeleka oluchazwe kwi-8.2.10 kwi-GB 7251.3-2005.

2. Iimpawu zesakhiwo seqokobhe lenqwaba yokutshaja yeshiti yesinyithi

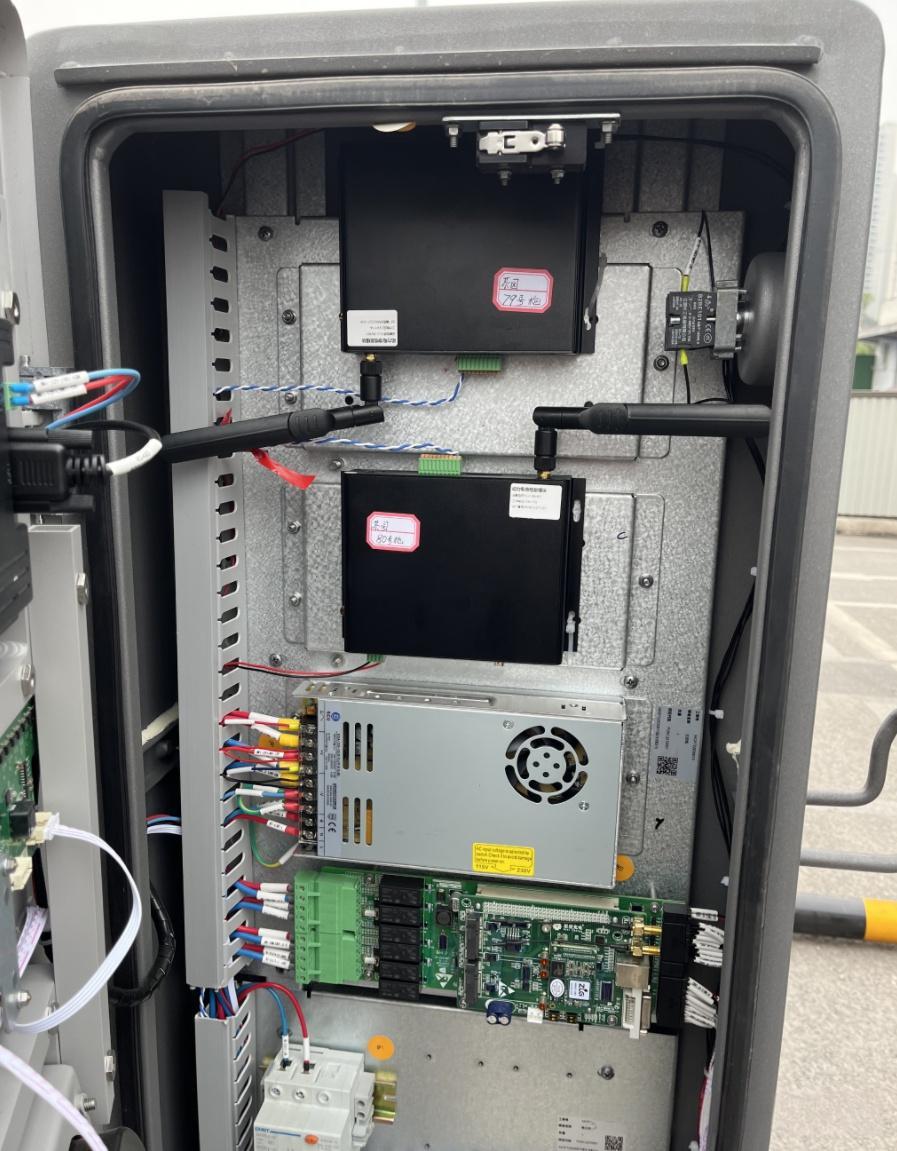

Iinqwaba yokutshajangokubanzi yenziwe ngumzimba wenqwaba yokutshaja,isokhethi yokutshaja, isixhobo sokulawula ukhuseleko, isixhobo sokulinganisa, isixhobo sokuswayipha ikhadi, kunye nojongano lonxibelelwano phakathi komntu nekhompyutha, njengoko kubonisiwe kumfanekiso ongezantsi.

Iphephainqwaba yokutshaja isakhiwo sesinyithiYenziwe ngepleyiti yentsimbi ekhabhoni ephantsi enobukhulu obumalunga ne-1.5mm, kwaye indlela yokucubungula isebenzisa inkqubo yokubhoboza, ukugoba, kunye nokwakha i-welding sheet metal tower. Ezinye iintlobo zee-charging piles ziyilwe ngesakhiwo esineengqimba ezimbini xa kujongwa iimfuno zokhuseleko lwangaphandle kunye nobushushu. Imilo iyonke yemveliso ikakhulu yingxande, isakhelo sidityaniswe sisonke, ukuqinisekisa ubuhle bembonakalo, umphezulu ojikelezileyo wongezwa kwindawo, kwaye ukuqinisekisa amandla ayo yonkeiinqwaba zokutshaja iimoto zombane, ngokuqhelekileyo idityaniswa ngezinto zokuqinisa okanye iipleyiti zokuqinisa.

Umphezulu wangaphandle wenqwaba udla ngokuhlelwa ngezalathisi zephaneli, amaqhosha ephaneli,iindawo zokutshajakunye nemingxunya yokusasaza ubushushu, njl.njl., ucango lwangasemva okanye icala lixhotyiswe ngesitshixo sokuthintela ubusela, kwaye inqwaba iqiniswe kwisiseko sofakelo ngeebholiti ze-anchor.

Izibophelelo ngokubanzi zenziwe ngentsimbi eqiniswe nge-electro-galvanized okanye i-stainless steel. Ukuqinisekisa ukubaisikhululo sokutshaja imoto yombaneUmzimba unokumelana nokugqwala okuthile, inqwaba yokutshaja idla ngokutshizwa ngepeyinti yomgubo wangaphandle okanye ipeyinti yangaphandle iyonke ukuqinisekisa ubomi bayo benkonzo.

3. Uyilo oluchasene nokugqwala kwesakhiwo sesinyithiinqwaba yokutshaja

(1) Inkangeleko yesakhiwo senqwaba yenqwaba yokutshaja akufuneki yenziwe ngeekona ezibukhali.

(2) Kucetyiswa ukuba isigqubuthelo esiphezulu seinqwaba yokutshaja ye-evinomthambeka ongaphezulu kwe-5° ukuthintela ukuqokelelana kwamanzi phezulu.

(3) Isixhobo sokususa umswakama sisetyenziselwa ukususa umswakama kwiimveliso ezivalwe kakuhle ukuthintela ukufuma. Kwiimveliso ezifuna ukususwa kobushushu kunye nemingxuma evulekileyo yokususa ubushushu, kufuneka kusetyenziswe isilawuli somswakama kunye neheater ukususa umswakama ukuthintela ukufuma.

(4) Emva kokuwelda ngesinyithi, imeko yangaphandle iyaqwalaselwa ngokupheleleyo, kwaye i-weld yangaphandle iwelda ngokupheleleyo ukuqinisekisa ukuba imveliso iyahlangabezana neemfunoI-IP54 engangeni manziiimfuno.

(5) Kwizakhiwo ezitywiniweyo ezitywiniweyo ezifana neziqinisi zephaneli yomnyango, ukutshiza akunakungena ngaphakathi kwesakhiwo sokutywina, kwaye uyilo luyaphuculwa ngokutshiza nokuhlanganisa, okanye ukutshiza iphepha le-galvanized, okanye i-electrophoresis kunye nokutshiza emva kokutshiza.

(6) Isakhiwo esidityanisiweyo masiphephe izithuba ezimxinwa kunye neendawo ezimxinwa ezingenakungena ngemipu yokutshiza.

(7) Imingxunya yokusasaza ubushushu kufuneka yenziwe ibe zizinto ezisetyenziswayo kangangoko kunokwenzeka ukuze kuthintelwe ukuwelda okuncinci kunye neengqimba ezidibeneyo.

(8) Intonga yokutshixa ethengiweyo kunye nehinge kufuneka zenziwe ngentsimbi engagqwali engama-304 kangangoko kunokwenzeka, kwaye ixesha lokumelana netyuwa engathathi cala akufuneki libe ngaphantsi kwe-96h GB 2423.17.

(9) Ipleyiti yegama iqiniswe ngeerivethi ezingaboniyo ezingangeni manzi okanye intlama yokuncamathelisa, kwaye unyango olungangeni manzi kufuneka lwenziwe xa kufuneka luqiniswe ngezikrufu.

(10) Ukukhethwa kwazo zonke izibophelelo kufuneka kuphathwe nge-zinc-nickel alloy plating okanye i-304 stainless steel, izibophelelo ze-zinc-nickel alloy ziyahlangabezana novavanyo lokutshiza ityuwa engathathi hlangothi kangangeeyure ezingama-96 ngaphandle komhlwa omhlophe, kwaye zonke izibophelelo eziveziweyo zenziwe nge-304 stainless steel.

(11) Izibophelelo ze-zinc-nickel alloy akufuneki zisetyenziswe kunye nentsimbi engagqwaliyo.

(12) Umngxuma we-ankile wokufakelwa kwe-iposi yokutshaja imoto ye-evkufuneka ilungiswe kwangaphambili, kwaye umngxuma awuyi kugqojozwa emva kokuba inqwaba yokutshaja ibekwe. Umngxuma wokungena ezantsi kwenqwaba yokutshaja kufuneka uvalwe ngodaka olungatshiyo ukuthintela ukufuma komphezulu ukuba kungangeni kwinqwaba ukusuka kumngxuma wokungena. Emva kokufakelwa, i-silicone sealant ingafakwa phakathi kwenqwaba kunye netafile yokufaka isamente ukuqinisa ukutywinwa komgangatho wenqwaba.

Emva kokufunda iimfuno zobugcisa ezingentla kunye noyilo oluchasene nokugqwala kwegobolondo lenqwaba yokutshaja yesinyithi, ngoku uyazi ukuba kutheni ixabiso lenqwaba yokutshaja enamandla afanayo okutshaja liya kwahluka kakhulu?

Ixesha leposi: Julayi-04-2025